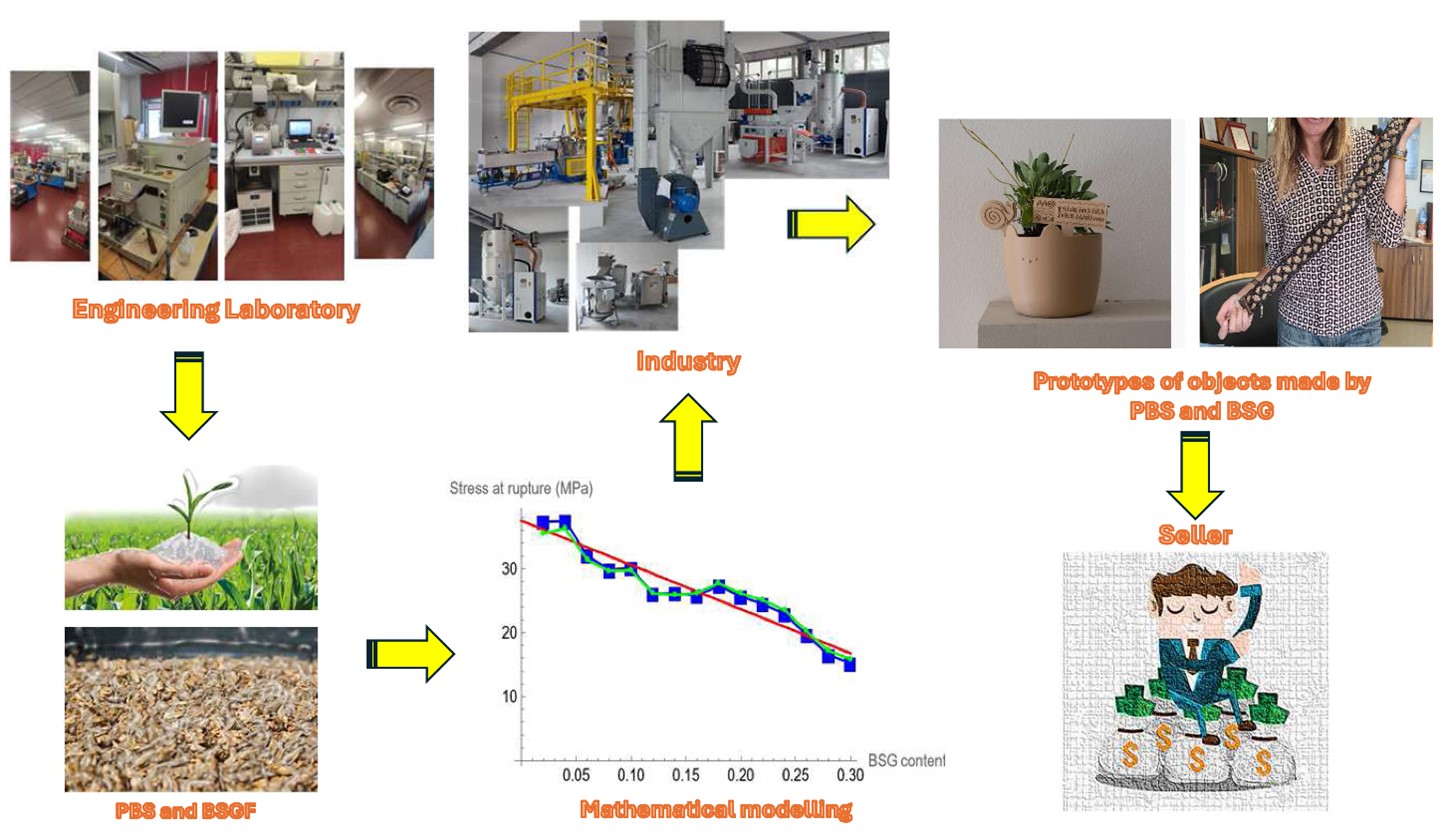

The UNIME team of the Department of Engineering led by Prof. Visco of the University of Messina has made available its scientific background in the field of materials engineering and transformation technologies of bio-plastics and bio-composites, for the transformation of agri-food waste of brewer spent grain into a resource and therefore into composite bioplastics, with a view to sustainable development. The UNIME team has designed and tested new formulations of bio-composites, (over 80 in number) using a combination of methodologies to optimize the quality and biodegradability of the final product, collaborating with other partners to translate the research results into practical applications.

In particular, the UNIME team has carried out the following activities:

- Construction of the MTP pilot plant for the processing of thresher grains on a pilot scale, following all the different phases:

I. Identification of a suitable location to host the plant;

II. Identification of the best plant technologies available on the market for the processing of brewer spent grain;

III. Request and start of administrative documentation for the procurement of quality control equipment and to prepare the tender process for the pilot plant;

IV. Review of technical offers with technical analysis of the proposed equipment and plants;

V. Design of the layout of the internal services of the laboratory (energy, instrumentation arrangement, compressed air);

VI. Selection of adequate laboratory instrumentation for the quality control of the brewer spent grain and bioplastic- brewer spent grain products;

VII. Selection of the appropriate compression system for the flow rate of the pilot plant;

VIII. Supervision of the installation of the plant by the winning company and use of the plant.

- Production of bio-composite mixtures followed by physical-mechanical analyses with various processing technologies to establish a database for scale-up to industrial level.

- Definition of the operating parameters for technological transformation on laboratory scale.

- Definition of the optimal size of the filler in the bio-composite.

- Definition of the optimal composition of the bio-composite constituents.

- Analysis of the influence of the presence of different additives.

- Optimization of mixtures with different qualitative and quantitative chemical composition and related systematic physical-mechanical-rheological-morphological analyses for the validation of the composition optimization.

- Development of an advanced mathematical model that allows us to correlate the chemical composition of the dredges with the physical and mechanical properties of the bio-composites, creating an essential database for the design of the final products.

- Analysis of the physical-mechanical characteristics of the bioplastic samples produced, following the biodegradation process.

- Recyclability tests of the bio-composites on a pilot scale (< 10 Kg).

- Tests to verify the transferability of the process to other agri-food waste.

(source: https://doi.org/10.3390/polym16212966)